What Are The Advantages Of The Mineral Insulated Cables?

Aug 08,2024

Aug 08,2024

Suke

Suke

In recent years, with the rapid development of the city, the number of high-rise buildings has soared, and the demand for electricity in the city has also risen. In such a densely populated area, the consequences of fire are unimaginable. According to the law, in the fire protection design code of building engineering, the fire protection system must use mineral-insulated cable to pass the fire protection acceptance.

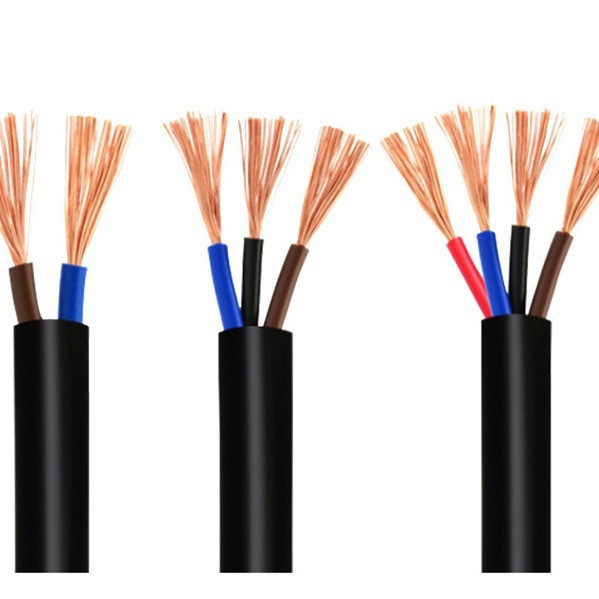

Mineral-insulated cable, referred to as MI cable, is generally called magnesium oxide cable or fire-resistant cable. It is a copper-core copper-sheathed cable insulated by the mineral magnesium oxide powder, and the mineral-insulated cable is composed of two inorganic materials: copper conductor, magnesium oxide, and copper sheath. Since the cable is all composed of inorganic substances (metal copper and magnesium oxide powder), it will not cause a fire itself; it is impossible to burn or ignite because the melting point of copper is 1083 °C and the melting point of magnesium oxide is 2800 °C, so the mineral-insulated cable can continue to maintain power supply in the case of a fire near the melting point of copper, making it a fire-resistant cable in a true sense.

1. Green environmental protection features

Cable structure materials are selected inorganic mineral materials; the cable in the burning flame does not release smoke or toxic gases. The discarded cables can also be fully recycled without polluting the natural environment.

2. Strong overload ability

The normal use temperature of mineral-insulated cables can reach 250 °C, and in special cases, mineral-insulated cable can maintain work for a short time at a temperature close to the melting point of the copper sheath. It is very suitable for laying in high-temperature places, such as metallurgy, boilers, glass furnaces, blast furnaces, and other environments. Its interception amount is also far greater than that of other cables because magnesium oxide powder has a better conductor coefficient than plastic, so at the same operating temperature, the interception amount is larger. For more than 16-mm lines, you can reduce a cross section; for places that do not allow people to contact, you can reduce two cross sections.

3. Good bending characteristics

Traditional rigid fireproof cable (BTTZ) is difficult to bend and use, and the bending radius of mineral-insulated flexible fireproof cable is at least 6 to 10 times the cable diameter, which reduces the space of the installation layout, reduces the installation cost, and is easier to lay.

4. Radiation resistance, no aging

Mineral-insulated cable adopts inorganic mineral-insulating material as insulation, which is not affected by radiation compared with conventional organic-insulated cable (YJV, VV); the material will not age or deteriorate, and the insulation characteristics will not change. At the same time, the outer sheath of the cable is in the form of copper rolling, with excellent sealing, moisture-proofing, and anti-corrosion, and the service life of the cable can reach more than 70 years, which is 2-3 times the life of the ordinary cable. Coupled with the characteristics of the copper sheath, the grounding of the cable is better, so the lightning protection grounding measures are effectively realized so as to ensure the safe and reliable operation of the electrical line.

5. High mechanical strength, anti-impact

The aluminum metal layer is arranged outside the mineral insulation layer of the cable, which has the effect of temperature insulation, heat insulation, fire blocking, and water blocking. It can also prevent objects in the fire environment from impacting the cable insulation layer, and the cable can be coated with a coated with a porcelain fire protection layer that will form a solid shell at 350 °C, effectively strengthening the protection function of the cable.

6. Longer continuous growth

Due to the use of continuous mechanized production, whether it is a single-core or multi-core cable, its length can fully meet the needs of the power supply length; the continuous length can reach more than 1000 m without the middle connection point, greatly reducing the safety risks caused by the connection point of the engineering line.

All in all, mineral-insulated cable is a special cable used in the construction of important national facilities, large public areas, high-rise buildings, and other places, and its fire resistance, durability, safety, reliability, and economy cannot be replaced by traditional power cables. Due to the many excellent characteristics of mineral insulated cables, which in recent years have been adopted by many domestic electrical design codes or standards, as well as in many engineering projects in different industries, it can be expected that in the next decade, the use of mineral insulated cables in China will increase significantly.

Home

Home What Is Shielded Cable And Damage Prevention Methods?

What Is Shielded Cable And Damage Prevention Methods?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address