What Is The Difference Between XLPE Cable And PVC Cable?

Jul 30,2024

Jul 30,2024

Suke

Suke

XLPE cable and PVC cable differ in the following six aspects. Let’s find out what it is.

1. Temperature Rating:

Generally, the maximum rated temperature of PVC cable is 70 ℃. However, the maximum temperature of XLPE cable can reach up to 90 ℃.

2. Service Life:

When the environment is good, the thermal lifetime of PVC cable is 20 years usually. Compared with PVC Cable, the XLPE cable can be used for 20 years longer. The thermal lifetime refers to the operating life of the cable as extrapolated under experimental standards.

3. Environment Friendliness:

When PVC burns, a large amount of black smoke and toxic HCI fumes will be released. But XLPE doesn’t release poisonous gas when it burns. As a result, using the XLPE cable is friendly to the environment.

4. Degree Of Danger:

If PVC cable burns, it will extend everywhere rapidly. The fire will spread in one or two minutes to make the power system lose power. In addition, the black smoke from burning cables can not only block your eyesight but also cause breathing and evacuation difficulties. What’s more, the main reason to result in death is toxic corrosive gases accompanying cable combustion. These toxic gases can also form dilute hydrochloric acid-conducting electrical film attached to electrical equipment, seriously reducing the insulating properties of the equipment and creating secondary damage that is difficult to remove.

5. Current Carrying Capacity:

Cross-linked polyethylene insulated cables have a higher current carrying capacity than PVC cables for the same conductor cross-sectional area.

6. Advantage:

PVC cable is a kind of flat tape cable. It is made of insulating material wrapped around a multi-stranded copper wire conductor, plus a sheath material which is then pressed together by automated equipment. Consequently, what makes the PVC cable connect and install easily is that it has characteristics such as flexibility and relatively thin thickness. Since XLPE cables have a higher current-carrying capacity than PVC cables, XLPE cables with a smaller cross-section can be selected for practical applications. In this way, less raw material is used and production costs are greatly reduced. The weight of the cable is reduced and it is also more favorable for installation.

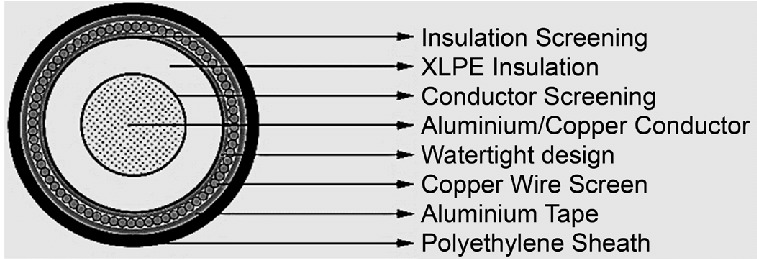

Structural defects make polyethylene often incapable of withstanding higher temperatures and inadequate mechanical strength, limiting its use in many applications. XLPE greatly improves its performance. Although PVC cables have a unique dominance, the performance of the XLPE cable is superior.

Home

Home What Is Low Smoke Zero Halogen Power Cable?

What Is Low Smoke Zero Halogen Power Cable?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address