Carbon Tariff Countdown: How Can Biobased Insulation Restructure The Cable Supply Chain?

Mar 19,2025

Mar 19,2025

Suke

Suke

The urgency of carbon tariffs and cable industry challenges

The EU Carbon Border Regulation Mechanism (CBAM) will be formally implemented in 2026, covering high-carbon industries such as power, steel and aluminum, and may be extended to more areas in the future. According to CBAM rules, products exported to the EU need to pay a carbon price difference, if the certified carbon emission data cannot be provided, the tax is calculated according to the EU default value (usually higher), which directly weakens the competitiveness of enterprises. The cable industry, as a traditional high-carbon industry, relies on petroleum-based plastics for the production of insulation materials, and its carbon emissions account for more than 90% of the supply chain. Therefore, switching to biobased insulation has become a key breakthrough to restructure the supply chain and cope with carbon tariffs.

Low-carbon advantages and technological innovation of bio-based materials

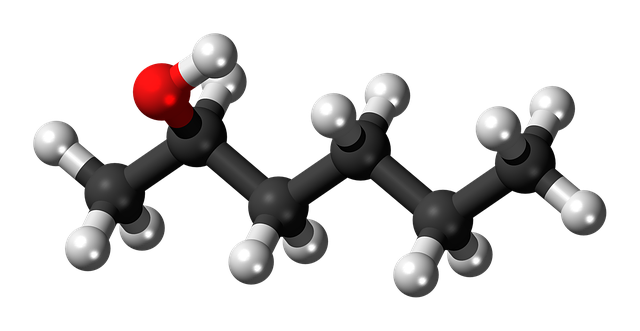

Bio-based insulation materials use renewable resources (such as plant fiber, polylactic acid, etc.) as raw materials, the carbon emission in the production process is significantly lower than that of petrochemical materials, and has degradable characteristics. The promotion of bio-based materials requires technological upgrading:

1. Production process innovation: research and development of low temperature and low pressure synthesis technology to reduce energy consumption;

2. Performance optimization: improve heat resistance and insulation to match traditional material standards;

3. Certification system interconnection: Establish a carbon emission accounting method that meets EU requirements to avoid high taxes due to missing data.

Supply chain restructuring: from data transparency to full chain collaboration

Carbon tariffs require companies to provide actual emissions data for more than 80% of their supply chains, involving multiple levels of supplier management. The application of bio-based materials requires the reconstruction of the following links:

1. Upstream raw material traceability: traceability of biobased raw materials through blockchain technology to ensure sustainability;

2. Midstream production integration: Promote joint development between cable manufacturers and biobased material suppliers to optimize production processes;

3. Downstream certification and market adaptation: Obtain international certification (such as EU CBAM recognition), and use differentiated pricing to enhance market competitiveness.

Policy coordination and industry ecological construction

The construction of the domestic carbon market and the revision of the Renewable Energy Law were accelerated to provide policy support for bio-based materials. For example, the state promotes the optimization of "new three" export logistics and encourages the layout of green supply chains. Enterprises need multi-party cooperation:

1. Production-university-research linkage: Joint universities to develop low-cost bio-based materials, such as Shandong carbon fiber industry through the innovation platform to break through the technical bottleneck;

2. Cross-industry alliance: Learn from the CCUS innovation consortium model established by 28 central enterprises to build a low-carbon technology sharing platform in the cable industry;

3. International negotiation engagement: Promote mutual recognition of carbon accounting and reduce trade barriers.

Future Outlook: From cost pressures to green opportunities

In the short term, the high cost of biobased materials may restrict adoption, but in the long term, the supply chain transformation forced by carbon tariffs will give rise to new business models. For example, Tencent data center reduces energy use costs through the "wind storage" microgrid, which confirms the economy of large-scale application of green technology. The cable industry can hedge costs through green electricity procurement, carbon sink trading, and transform low-carbon certification into a brand premium, reshaping the global supply chain discourse.

Conclusion

Bio-based insulation is not only a tool to deal with carbon tariffs, but also the fulcrum of the cable industry's transition to green manufacturing. Through technological innovation, data transparency and ecological synergy, Chinese companies are expected to restructure their competitiveness under low-carbon trade rules and achieve a shift from "passive compliance" to "active leadership".

Home

Home How Do I Qualify For Cable Recycling In The United States?

How Do I Qualify For Cable Recycling In The United States?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address